Self-copying form is the paper glued at the edges, transferring the information deposited on it to the next layers by chemical copying.

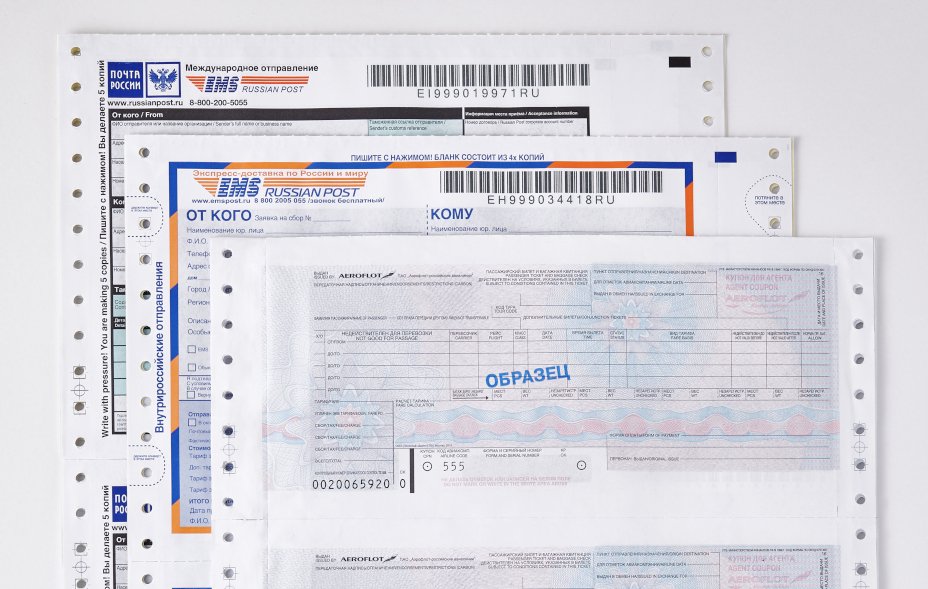

Polygraph-Zashchita SPb" is the expert in the field of producing air documents

The company reached its high professional level during the period of multilayer self-copying tickets production. The slip of the ticket was printed in full compliance with requirements to the protected printing products of "B" category and contained 13 numbered self-copying forms fastened in a single slip.

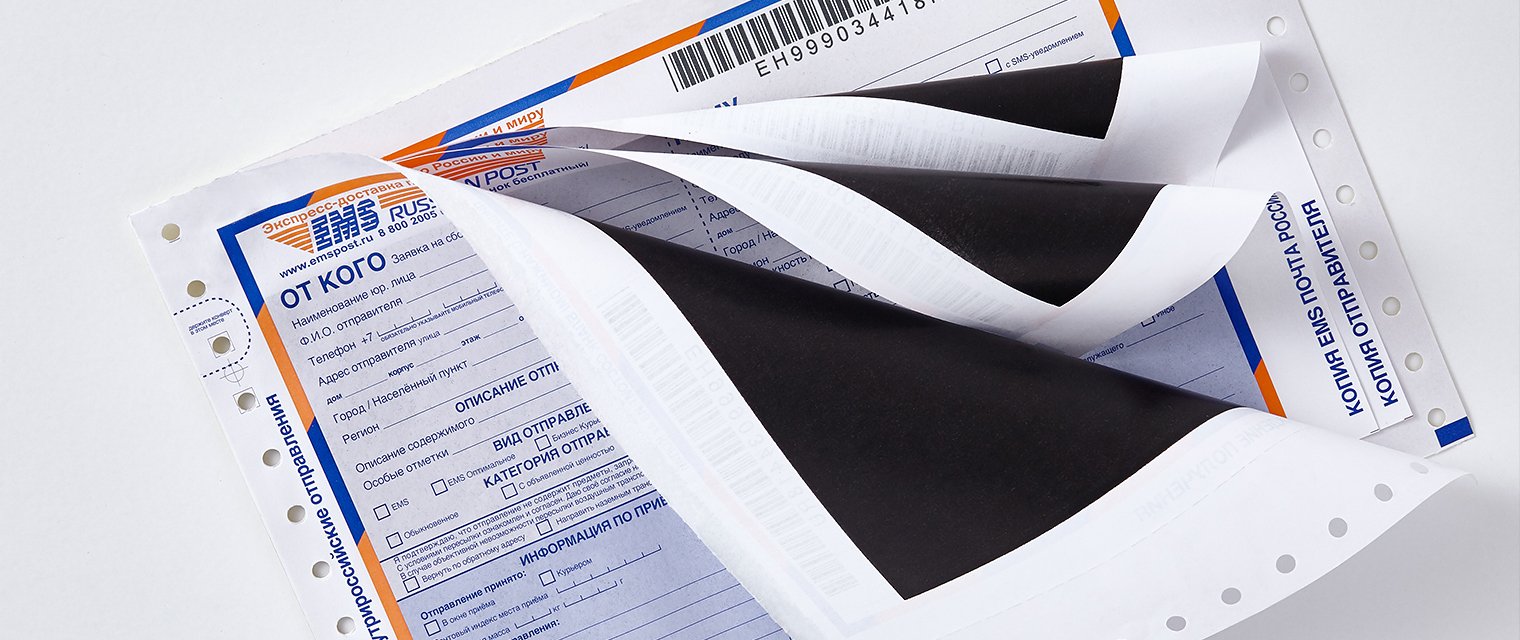

Self-copying forms are widely in demand in the market of express shipments. Proper registration of details and transfer of the shipment from the customer to the courier should take the shortest time possible. The forms must contain all necessary information about the sender and recipient of the shipment. Any material shipment is packed in the form of an envelope or a packing box and acquires the final functional form only after pasting the form of the courier or consignment note or the form-pack E1. All these forms have a similar design as a set of self-copying forms with repeated details on each sheet. They differ mainly in design and number of sheets included. As for the forms design, here the customer is not limited in the choice of colors, security elements and lines of tear-off perforations.

We produce forms for a variety of organizations: banks, transport and insurance companies. The number of layers of the form depends on the specifics of their business processes: sometimes there are up to 13 of them. We can print as many layers as the customer needs.

There are two main copying technologies. The first method is capsular one: there is physical contact between the copied layers, in which the capsule-containing reagents enter into a chemical reaction that manifests the place of contact, painting it black. There are four abbreviations for self-copying papers: SC, CB, CF, CFB. The SC layer is copied on itself; the CB layer is the upper part paired with the CF layer; the CFB layer is intermediate in the multilayer structure. As a rule, capsule technology is used in constructions of no more than six forms. This is due to the fact that the quality of the copied image depends on the compression of the copying layers. The effort should be enough for the capsules to burst and interact with each other. Under pressure (by matrix printer or an ordinary pen), the paint is transferred to the subsequent layers: opened microcapsules, located on the reverse side of the sheet, release a special liquid that causes a reaction on the next sheet of self-copying form. Thus, the information appears on the next layer of the form. Imprint colors: black, blue-standard; red, green-on request.

The second method is carbon one. At copying carbon pains, there`s the layer separation of the ink, wherein the adhesion strength of the receiving paper exceeds the cohesive force between the inner paint layers. Carbon copy layers provide greater contrast when copying, allow you to copy information to a depth of 13 layers, have a longer service life.

Our company can produce self-copying forms of any design using capsule and carbon copying technologies. Layout options: as an endless form, and by formats.